Dive into Accuracy: Materials Test Lab Precision Unleashed

Wiki Article

Placing Products to the Examination: Discovering the Duty of Products Examination Labs

Products test labs play a critical function in ensuring the high quality and integrity of various products used in markets such as aerospace, production, and building and construction. Via a combination of sophisticated strategies and specialized equipment, materials examination laboratories are able to assess the residential properties of steels, polymers, composites, and other materials under numerous conditions and stressors. This post will certainly explore the significance of materials screening, the kinds of products examined, testing techniques and devices utilized, as well as the applications of products examination results.Relevance of Products Screening

Routinely examining the high quality of products is vital in making certain the honesty and safety of items in numerous sectors. This is where products screening plays an essential duty. Products screening includes subjecting materials to different tests and experiments to assess their mechanical, physical, and chemical homes. By carrying out these manufacturers, distributors and examinations can guarantee that their products fulfill the called for requirements and specifications.One of the key factors why materials screening is very important is the guarantee of product quality. With rigorous testing, suppliers can determine any kind of problems or weak points in the products used for their products. This allows them to make required renovations to enhance the total quality and efficiency of their products. Materials screening aids in identifying prospective concerns that may develop throughout the product's lifecycle, such as wear and tear, rust, or architectural failures. By attending to these concerns at an early stage, suppliers can prevent expensive recalls, legal actions, and reputational damage.

By subjecting products to different tests, suppliers can identify their stamina, resilience, and resistance to external aspects such as heat, stress, or chemicals. Whether it is automobile components, medical devices, or building products, products screening helps in recognizing any type of possible security threats and establishing appropriate procedures to mitigate them.

Kinds Of Products Evaluated

Different kinds of materials are examined in products examination laboratories to examine their mechanical, physical, and chemical buildings. These materials can incorporate a vast array important, including steels, polymers, ceramics, compounds, and also natural materials such as timber and concrete.Steels are frequently checked due to their extensive use in various sectors. Compounds, which are composed of two or more different products, are examined to comprehend their overall performance, consisting of aspects like versatility, strength, and durability.

All-natural materials like timber are checked to evaluate their toughness, wetness content, and resistance to degeneration (materials test lab). Concrete is one more commonly tested product, with tests concentrating on its compressive stamina, durability, and resistance to ecological elements

In enhancement to these materials, materials examination labs also evaluate finishes, paints, adhesives, and numerous other materials used in construction, manufacturing, and various other sectors. By subjecting these materials to strenuous testing, designers and scientists can gather useful information to inform product option, design optimization, and top quality control processes.

Checking Strategies and Equipment

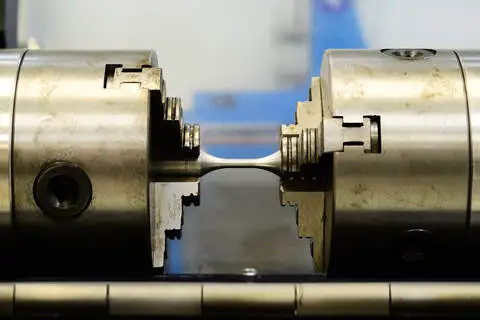

Evaluating strategies and equipment play a vital role in materials test laboratories for evaluating the mechanical, physical, and chemical buildings of various materials. These methods and tools are essential in guaranteeing the high quality, integrity, and safety and security of materials used in different markets such as aerospace, vehicle, building and construction, and clinical.One commonly used testing technique in materials test labs is mechanical testing, which includes subjecting materials to different forces or tons to identify their stamina, firmness, ductility, and various other mechanical residential properties. This is often done using tools such as global screening machines, which can apply tensile, compressive, and flexing pressures to evaluate samplings.

Physical testing techniques are also utilized to analyze properties such as density, thickness, thermal conductivity, and electric conductivity. Devices such as density meters, viscometers, thermal conductivity analyzers, and electrical conductivity meters are used to perform these examinations properly.

Chemical testing techniques are used to determine the chemical make-up and pureness of materials. Techniques such as mass, spectroscopy, and chromatography spectrometry are frequently utilized, along with customized devices developed for these purposes.

Applications of Materials Test Results

The results of products testing provide valuable insights right into the efficiency and viability of various products for particular applications in different industries - materials test lab. These test results play an essential role in determining the quality, durability, and safety of products made use of in producing processesOne of the vital applications of products test results remains in the area of building. Engineers and designers count on these results to pick proper materials for building frameworks, such as bridges, high-rise buildings, and domestic structures. By performing tests on products like steel, concrete, and lumber, they can make certain that these products meet the called for requirements and can withstand numerous environmental problems.

In the aerospace market, materials examination results are necessary in identifying the look at here now viability of materials for airplane elements. By subjecting products to extensive screening, engineers can analyze their mechanical buildings, resistance to heat and deterioration, and ability to hold up against high-stress conditions. This details is crucial in making certain the safety and integrity of aircraft.

Future Patterns in Products Testing

In the world of materials screening, developments in products evaluating techniques are shaping the trajectory of the area, introducing a new age of advancement and precision. As technology remains to advance, so does the need for even more advanced screening techniques and equipment. One future trend in products screening is the assimilation of expert system (AI) and artificial intelligence algorithms into screening procedures. These technologies have the possible to enhance the performance and precision of examination outcomes by analyzing big quantities of information and recognizing patterns that may not be conveniently detectable by humans. Furthermore, using non-destructive screening approaches is coming to be significantly preferred. These methods permit the assessment of material homes without creating damages or alteration to the sample, making them perfect for evaluating useful or irreplaceable products. There is a growing focus on sustainability in products screening. This consists of the advancement of screening techniques that reduce waste and energy consumption, as well as making use of environmentally-friendly products in screening devices. Generally, the future of materials testing is characterized by continual technology and a dedication to enhancing accuracy, efficiency, and sustainability.Final Thought

In verdict, products screening plays a critical role in various industries by ensuring the quality, safety, and performance of materials used in products and structures. The outcomes acquired from materials testing are used to make informed decisions in material layout, manufacturing, and option processes.Through a combination of advanced strategies and customized devices, materials examination laboratories are able to examine the residential properties of steels, polymers, composites, and other products under different conditions and stress factors. By performing tests on materials like hardwood, concrete, and steel, they can make sure that these materials fulfill the needed requirements and can withstand numerous environmental problems.

In the aerospace sector, products examination outcomes are important in identifying the suitability of materials for aircraft components. By evaluating materials for their resistance, strength, and versatility to effect, manufacturers can pick the most suitable materials for various auto parts, such as body panels, engine parts, and safety features.In try this out the world of products screening, innovations in products evaluating approaches are forming the trajectory of the area, ushering in a brand-new age of development and accuracy.

Report this wiki page